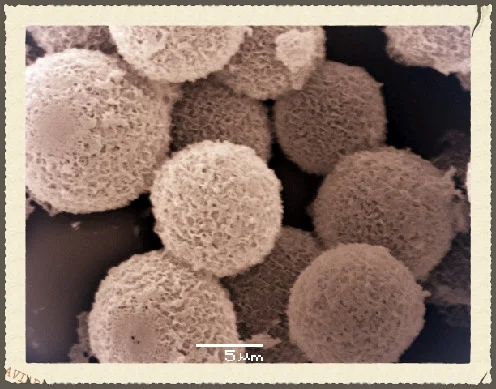

In the field of colloid science the ability to fabricate particles with a defined shape, other than a sphere, has gained attention. The reason is that anisotropy in shape and/or chemical composition can lead to interesting physical properties when these particles are dispersed in a liquid, or when they form part of a product formulation. We report an insight into the synthesis of silica-based “matchstick”-shaped colloidal particles, which are of interest in the area of self-propulsion on small length scales. The generation of aqueous emulsion droplets dispersed in an n-pentanol-rich continuous phase and their use as reaction centers allows for the fabrication of siliceous microparticles that exhibit anisotropy in both particle morphology, that is, a “matchstick” shape, and chemistry, that is, a transition-metal oxide-enriched head. We provide a series of kinetic studies to gain a mechanistic understanding and unravel the particle formation and growth processes. Additionally, we demonstrate the ability to select the aspect ratio of the “matchstick” particle in a straightforward manner.

The paper is recently published in Langmuir. DOI:10.1021/acs.langmuir.5b02645