BONLAB BLOG

Thoughts

&

Scientific Fiction

Visualizing the drying and film formation of polymer latexes

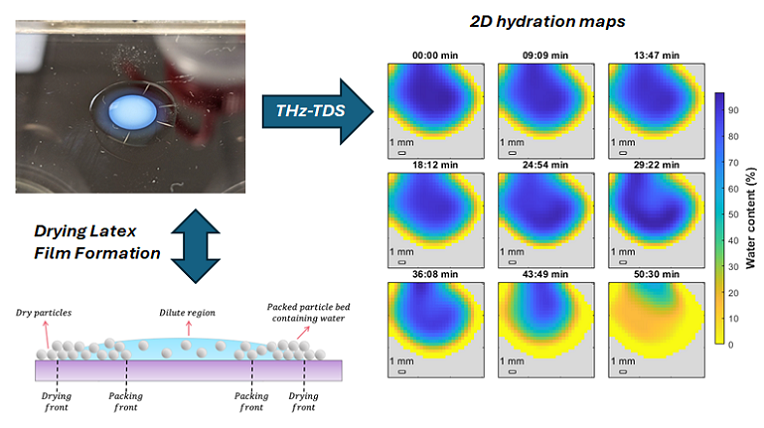

Polymer latex particles, typically 50-600 nm in diameter, are used in many applications, such as paper manufacturing, water-based adhesives, printing, and coatings. Commonly, a water-based formulation that contains these polymer colloids is used, often together with other components, such as pigments for opacity and color, fillers, and rheology modifiers. Each of the polymer latex particles consists of many individual polymer chains. These water-based dispersions are applied onto a substrate as a droplet or a film, after which these systems are dried. Visualizing this drying and film formation process in real time would greatly help in understanding how the properties of a dried film come about. In our paper, published in the American Chemical Society’s journal Langmuir, we used TeraHertz Time-Domain Spectroscopy (THz-TDS) to map the water content spatially in real-time during the drying process.

Polymer latex particles, typically 50-600 nm in diameter, are used in many applications, such as paper manufacturing, water-based adhesives, printing, and coatings. Commonly, a water-based formulation that contains these polymer colloids is used, often together with other components, such as pigments for opacity and color, fillers, and rheology modifiers. Each of the polymer latex particles consists of many individual polymer chains. These water-based dispersions are applied onto a substrate as a droplet or a film, after which these systems are dried. Upon evaporation of water, the individual components will pack closely. When little water remains in between, a so-called capillary under-pressure facilitates tight packing, and if the polymer latex particles are soft, it deforms them. The last stage of the film formation process is when polymer chains from one latex particle now diffuse into a neighboring latex particle and the other way around. This process ensures that the dried film has good adhesive and mechanical properties.

Visualizing this drying and film formation process in real time would greatly help in understanding how the properties of a dried film come about. In our paper, published in the American Chemical Society’s journal Langmuir, we used TeraHertz Time-Domain Spectroscopy (THz-TDS) to map the water content spatially in real-time during the drying process.

The use of TeraHertz Time-Domain Spectroscopy (THz-TDS) as a tool to visualize the water content in a drying polymer dispersion in real-time.

Emily Brodgen, a final year PhD researcher from BonLab, teamed up with Gonçalo Costa, a PhD researcher in the Department of Physics at the University of Warwick, working with the team of prof. Emma Pickwell-MacPherson, and together they studied the potentials THz-TDS could bring.

Prof. dr. ir. Stefan Bon says: “It is great to see this collaborative work. We believe that there are opportunities for THz-TDS to be used as an analytical tool in the field of water-based polymer dispersions, particularly how droplets or films dry after they have been deposited onto a surface. As you can read in the paper, which we very much see as a positioning study, there are great opportunities out there to refine the technique. We hope others are as enthusiastic as we are so that THz-TDS can be adopted wider as a measurement tool.”

The paper is freely available to all from ACS Langmuir and can be found here:

https://doi.org/10.1021/acs.langmuir.4c03103

For more information, please get in touch with prof. dr. ir. Stefan A. F. Bon directly.

Templating Calcium Phosphate onto Graphene Oxide Sheets

Single-layer graphene oxide sheets are interesting as a flexible 2D material, with xy-dimensions variable up to a centimetre in length and a z-thickness of a single carbon atom. The presence of oxygen atoms with functional groups, such as hydroxy, epoxy, carboxylic acid, ketone, or aldehyde, provides graphene oxide (GO) with polarity. This unique property allows GO to disperse as single sheets in polar solvents like water or DMSO at low concentrations, in the absence of electrolytes or other colloidal particles.

Single-layer graphene oxide sheets are interesting as a flexible 2D material, with xy-dimensions variable up to a centimetre in length and a z-thickness of a single carbon atom. The presence of oxygen atoms with functional groups, such as hydroxy, epoxy, carboxylic acid, ketone, or aldehyde, provides graphene oxide (GO) with polarity. This unique property allows GO to disperse as single sheets in polar solvents like water or DMSO at low concentrations, in the absence of electrolytes or other colloidal particles.

Our recent findings, published in RSC Polymer Chemistry (https://doi.org/10.1039/D4PY00300D), have shown that grafting polymer chains from the surface of GO significantly enhances its dispersion. This is particularly true when the polymer chains are of a branched chain architecture. The grafted branched polymer chains provide additional electrostatic and steric stabilization against sheet stacking and crumpling, a discovery that could have significant implications in the field of materials science.

SEM images of single graphene oxide sheets that are decorated with a layer of calcium phosphate, deposited to a templated synthesis route.

The 2D architecture of single GO sheets dispersed in water is an exciting template for depositing inorganic materials, especially now that the grafted polymer chains can be engineered to withstand the ionic precursor concentrations so that the sheets remain dispersed and can additionally serve as crystal nucleation sites.

In our paper published in the Journal of Colloid and Interface Science we show that it is possible to grow Calcium Phosphate onto single dispersed sheets of GO in water. The work was led by former PhD researcher dr. Wai Hin Lee.

Prof. dr. ir. Stefan Bon says: “This paper shows that as a result of the grafted branched polymer, the use of dispersed Graphene Oxide sheets as a template for mineralization is now possible and straightforward. It opens up all sorts of possibilities for hybrid material design”

You can read the paper here: https://doi.org/10.1016/j.jcis.2024.06.221

Water-Based Acrylic Latexes are excellent Pressure Sensitive Adhesives when Branched

Water-based pressure sensitive adhesives (PSAs) are typically made by emulsion polymerization using a low glass transition temperature base monomer, such as n-butyl acrylate or 2-ethyl hexylacrylate, together with a range of functional comonomers. Typically these include a high glass transition temperature comonomer, such as styrene or methyl methacrylate and monomers that can promote wetting and undergo secondary interactions such as (meth)acrylic acid.

Water-based pressure sensitive adhesives (PSAs) are typically made by emulsion polymerization using a low glass transition temperature base monomer, such as n-butyl acrylate or 2-ethyl hexylacrylate, together with a range of functional comonomers. Typically these include a high glass transition temperature comonomer, such as styrene or methyl methacrylate and monomers that can promote wetting and undergo secondary interactions such as (meth)acrylic acid.

A golden rule for good adhesive performance is that the polymer latex particles must contain a certain fraction of gel, that is, cross-linked material. This typically is 50-70%. This gel content optimizes the balance between tack and cohesive forces within the adhesive.

Schematic of the branched polymer chain architecture approach to deliver good performance in pressure sensitive adhesives (PSAs).

In our paper, led by PhD researcher Emily Brogden and published in the RSC journal Polymer Chemistry, we challenged this view. Prof. dr. ir. Stefan Bon says: “We designed a range of polymer latexes with low gel content. To balance the adhesive forces, we introduced a branched polymer chain architecture instead. We show that excellent water-based acrylic PSAs can be made using this approach.”

Moreover, the chemical composition of our PSA was designed with sustainability in mind. The base monomer selected was the bio-based 2-octyl acrylate, the high Tg component bio-based 2-isobornyl acrylate. The other monomers and chain transfer agent show promise to be or become fully bio-based.

The paper entitled “Water-Based Polymer Colloids with a Branched Chain Architecture as Low-Gel Pressure-Sensitive Adhesives” has gold open access and can be read here: